Technical data

| Max die cutting area | 350 x 500 mm |

| Max hot foil stamping area | 240 x 480 mm |

| Waste min/max: | Direction of travel waste: min. 9 mm Lateral direction waste: min. 10 mm |

| TWO POSSIBILITIES FOR MAXIMUM FORMAT SIZE: |

Single stroke: Max sheet size (width x length): 550 x 380 mm Multiple stroke: Max sheet size (width x length): 550 x 710 mm |

| Min. sheet size | 220 x 220 mm |

| Min/Max thickness of material paper, card, etc... | from 120 g/m2 to 4 mm |

| Power: | 5 kW, 8.5 kW with hot foil stamping |

| Cutting force: | 60 ton (600,000 N) with 350 g/m2 |

| Max working speed: (dependent on number up) | Single stroke up to 2400 sheets/hour |

| Compressed air requirement: | 250 l/min at 6 bar |

| Electrical connection: | 3PH, 400 V + N + T, 50 Hz (Neutral and earth must be separate; if this is not possible, a transformer may be requested at additional cost) |

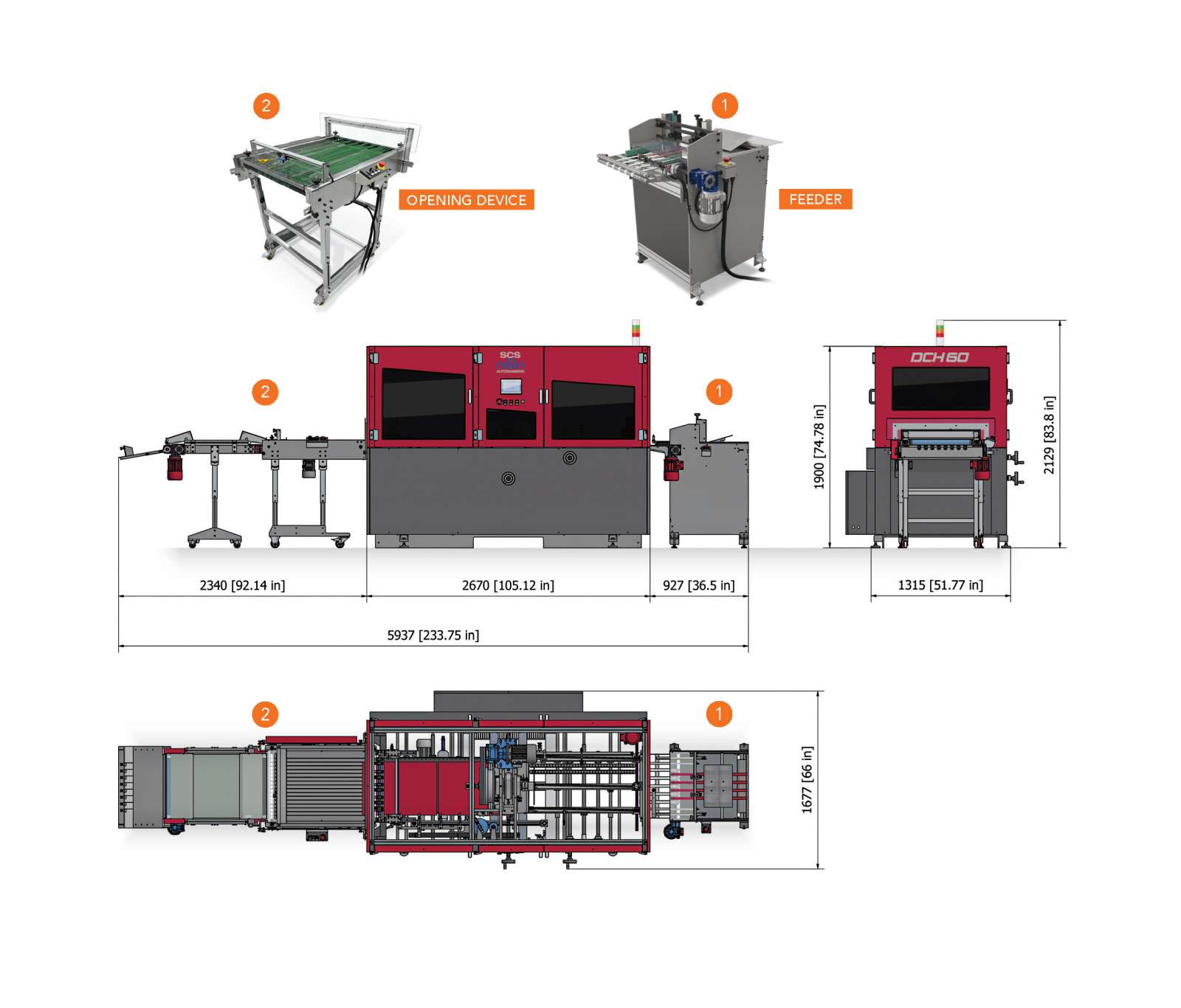

| Machine dimension (L x D x H) | 2650 x 1750 x 1915 mm |

| Machine dimension with feeder, separation and collection belts (L x D x H) | 6240 x 1750 x 1915 mm |

| Machine weight | 2200 kg |

Technical data subject to change without notice

Example of possible in-line configuration

DCH60IT

DCH60IT  DCH60ENG

DCH60ENG  DCH60_ES

DCH60_ES