- Home

- Product Range

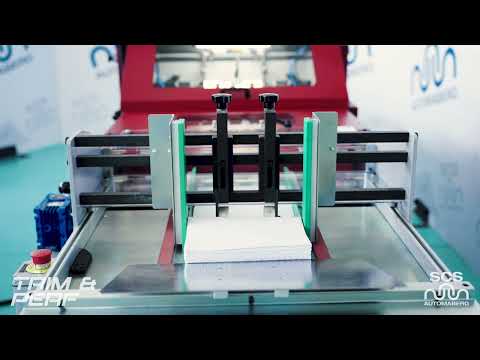

- Trim & Perf

Die cut, trim, split, cut, perforate, punch, perfectly

QUALITY GUARANTEE

A highly versatile and productive line which is a genuine “ALL-IN-ONE” solution for finishing operations.

The line can include different work stations for multiple tasks and process optimisation. The combination of TRIM&PERF with complementary modules offers high quality products combined with reliability, allowing the needs of digital systems to be met, as well as those for binding and, in particular, the production of specific products for single and multi-up work IN A SINGLE PASS.

Our company specialises in “ON DEMAND” products and is always able to offer NON-STANDARD solutions.

ADVANTAGES

- Easily moveable

- In-feed belt table adjustable in height for easy connection with upstream machines

- The complementary modules allow an easy connection IN-LINE with other machinery

- Handles any material

- By simply pushing a button TRIM & PERF is transformed into a regular conveyor belt, no bypass or similar equipment needed

- The production of specific products also on request, will be met by the use of different accessory tools and the complementary modules

COMPLEMENTARY EQUIPMENT

- + CONTINUOUS FEEDER Rubber belt type for folded and saddle stitched products and perfect bound books.

- + 3 WAY This module allows perfect alignment of digital sheets to a print reference mark.

- + WASTE EJECTION The system allows diecutting without waste, clean shape products.

- + THERMO STICK Sticks together some sheets on the ink reference sides by thermo welding - improving the die cutting production process.

- + PRE-CUT DEVICE Perfect 'spine' cutting system up to 14 mm thickness.

- + TEAR OFF - PULL AWAY The system pull away mingled perforation sheets in preparation for the sewing step.

- + SIMPLE DECK Collect cards in series after die cutting.

- + EXIT BELT Shingle delivery belt with batch counter.

AN ALL-IN-ONE SOLUTION FOR ALL YOUR FINISHING NEEDS

DIE CUTTING- No nicks! Connections between the cut product and the waste are not required

- Automatic waste ejection

- 'Clean' shapes ready to be packed

Superior quality in splitting and trimming - also for very small dimensions

ROUND CORNER CUTTINGCutting including all four corners in a single pass

PERFORATING PUNCHINGCombined perforating-punching jobs in a single pass to optimize production process efficiency

IDEAL FOR

- FLAT CARDBOARD, ALSO LAMINATED UP TO 2 mm thickness

- + 3 WAY PERFECT ALIGNMENT OF DIGITAL SHEETS TO A PRINT REFERENCE MARK

- Folded and stitched product die cut without waste

- NON STANDARD SOLUTION ON DEMAND also on plastic material up to 1 mm thickness

- + PRE CUT DEVICE PERFECT SPINE CUTTING SYSTEM up to 14 mm thickness

- Standard radii from 3 to 15 mm

- stamp perforating, wire-comb perforating, tear-off perforating, single hole punching, file hole punching, euro hole

Technical Data

| Product size untrimmed (LxW) sizes subject to jobs |

standard max. 500 x 600 mm standard min. 50 x 50 mm |

| Product thickness | standard max. 4mm optional max. 14mm |

| Speed max. mechanical | 9.000 cycles/hr |

| Installed power | 3 kW * |

| Compressed air requirement | 200 l/min at 6 bar * |

| Weight | 700 kg * |

| Dimensions (LxWxH) | 2,000 x 1,360 x 1,200 mm * |

Technical data subject to change without notice

* Values refer to the basic model

- Cardboard

- Laminated Board

- Folded Products

- Stitched Products

- Soft Cover Books

- Book Blocks

- Hard Cover Board

- Foam Board

- Plastic sheets 1 mm thickness

- Diecutting

- Trimming

- Splitting

- Perforation

- Punching

- Corner Cutting

- Side trimming

- Front trimming

- Stamp perforating

- Wire-comb perforating

- Tear-off perforating

- Single hole punching

- File hole punching

- Tab-cutting

- Euro hole

TeP_IT

TeP_IT  TeP_EN

TeP_EN  TeP_ES

TeP_ES